Craft breweries have taken the beer industry by storm in recent years, offering a diverse array of unique and flavorful brews. Behind the scenes of every successful craft brewery, you’ll find a hidden hero – the conveyor system. While it may not be as glamorous as the brewing equipment or the taproom, conveyors play a pivotal role in the brewing process, ensuring efficiency, consistency, and quality. In this article, we’ll explore the crucial role conveyors play in craft brewery operations.

Raw Material Handling

Precision Movement: Dorner conveyors are renowned for their precise control over material movement. In raw material handling, this translates to consistent and even distribution of ingredients like malted barley. The conveyors’ adjustable speed and load capacity control ensure that the right amount of material is delivered to the mill or mash tun, contributing to the brewing process’s efficiency and accuracy.

Customization: Each craft brewery has its unique setup and requirements. Dorner conveyors offer a high degree of customization, allowing breweries to tailor the conveyors to fit their specific needs. Whether it’s accommodating different grain types, adapting to various container sizes, or adjusting to specific angles and heights, Dorner conveyors can be configured for seamless integration into any brewery’s layout.

Mash Tun and Lautering

Precise Mixing: Achieving an even mixture of grist and water in the mash tun is vital for efficient mashing. Dorner conveyors with adjustable speed controls and timed retracting tails ensure that the grist is incorporated evenly into the water, facilitating optimal starch conversion and flavor extraction.

Hygienic Design: Dorner conveyors are engineered with sanitation in mind. They feature easy-to-clean surfaces and stainless-steel options, reducing the risk of contamination during the mash and lautering processes. This emphasis on cleanliness helps maintain the integrity of the beer and ensures consistent quality.

Fermentation and Maturation

Gentle Handling: Dorner conveyors handle beer transfer between fermentation and maturation vessels with precision and care. Their smooth and gentle movement minimizes agitation and reduces the risk of oxygen exposure, a critical factor in preserving the beer’s flavor and aroma during maturation.

Robust Construction: The durability of Dorner conveyors is well-suited to the demanding conditions of brewery operations. Their sturdy construction can withstand the weight and pressure associated with transferring large volumes of beer, ensuring reliability and longevity.

Packaging

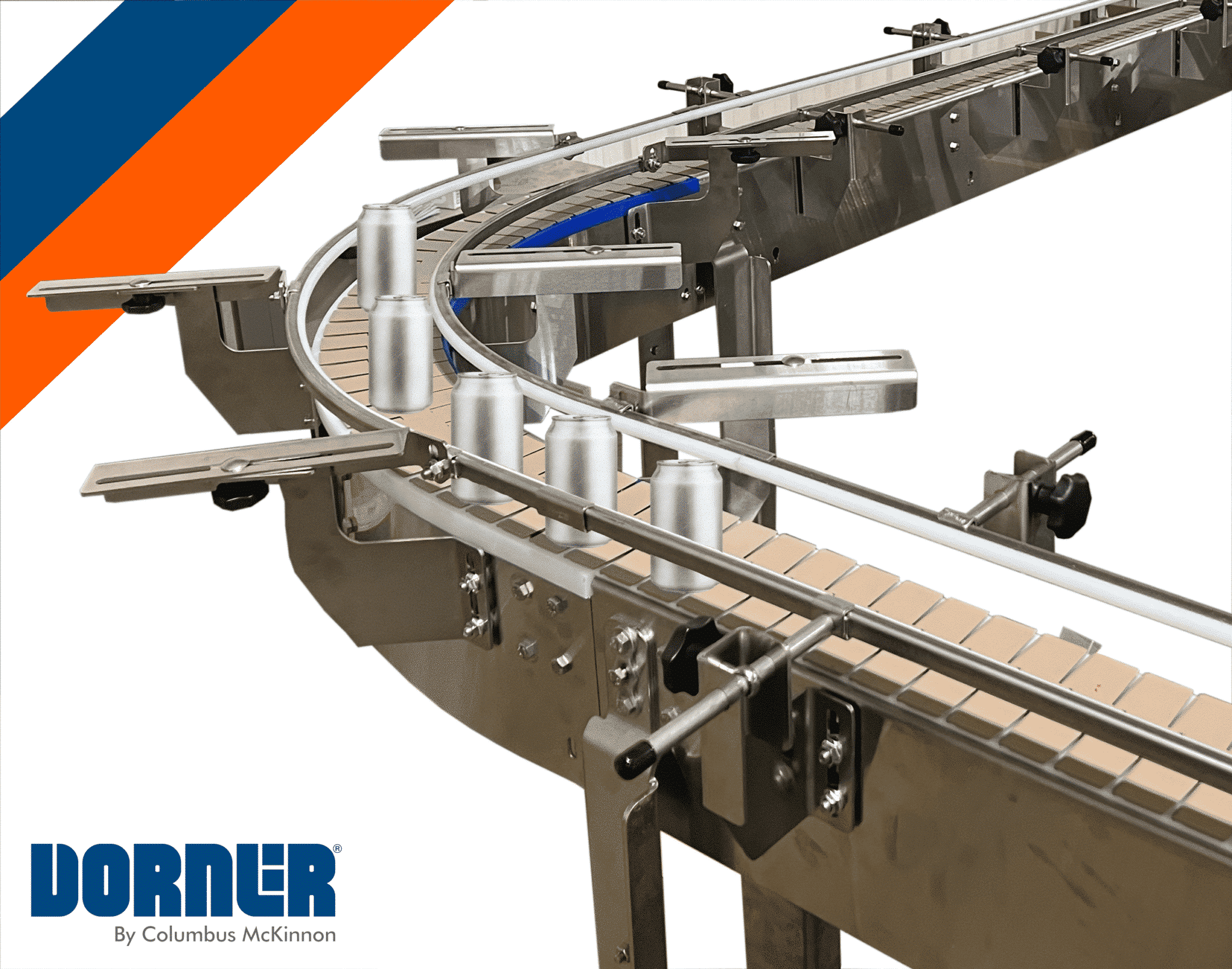

Consistent Filling: Dorner conveyors excel in packaging by ensuring consistent filling levels in bottles, cans, and kegs. The conveyors can be equipped with accurate sensors and controls that maintain precise filling, reducing the likelihood of underfilling or overfilling containers.

Accumulation: Garvey, a fellow Columbus McKinnon brand company, specializes in bottling accumulation, with their variety of accumulation tables that move bottles delicately and aggregate them into the correct packaging line keeping throughput at optimal levels.

Quality Control

Integration with Monitoring Systems: Dorner conveyors seamlessly integrate with quality control systems, including vision systems and sensors. These systems can detect irregularities in the product, such as mislabeled bottles or defective packaging, allowing for immediate removal from the production line. This level of automation ensures that only high-quality beer reaches consumers.

Safety and Ergonomics

Reduced Manual Labor: By automating material handling processes, Dorner conveyors reduce the need for manual labor, which can be physically demanding and repetitive. This not only enhances the efficiency of brewery operations but also contributes to a safer and more comfortable working environment for brewery staff

While they may not be the stars of the show, Dorner conveyors are the unsung heroes of craft brewery operations. Their precision, customization options, and focus on sanitation make them an ideal choice for breweries of all sizes. By partnering with Dorner, craft breweries can ensure that their processes run smoothly, their products meet the highest quality standards, and their staff enjoys a safer and more ergonomic working environment. Dorner conveyors are a valuable tool for the craft brewing industry, contributing to the creation of exceptional and consistent beer experiences for consumers. Cheers to the efficiency and reliability of Dorner conveyors in craft brewery operations!